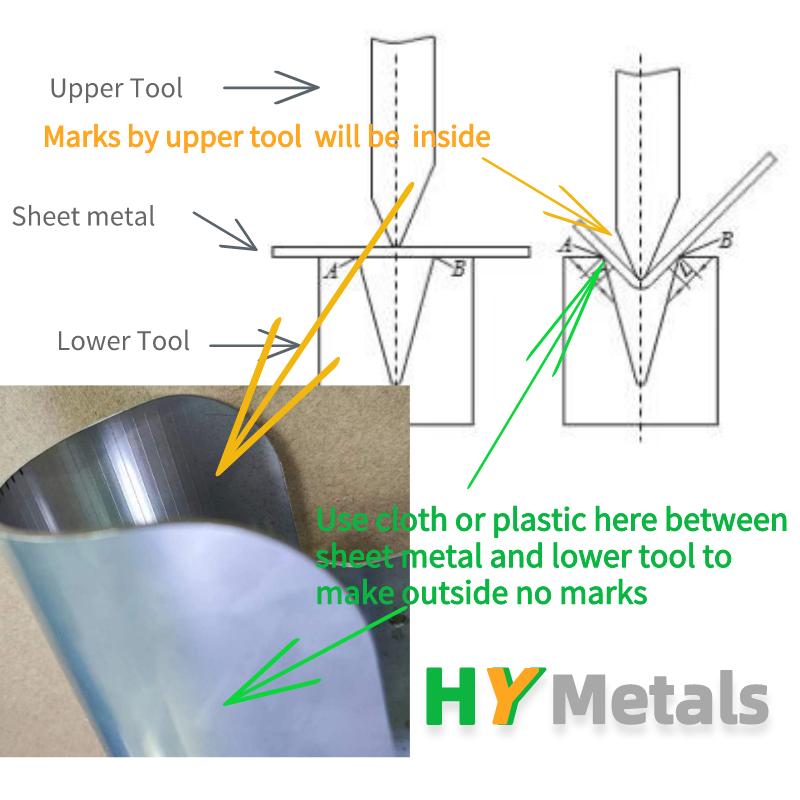

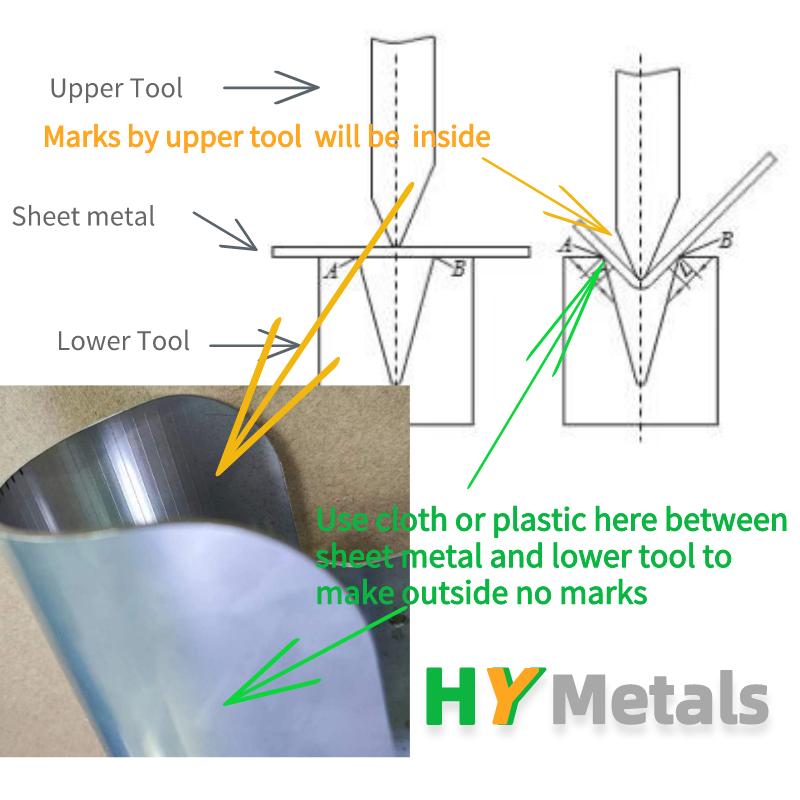

To avoid bend marks, the sheet metal should be covered with cloth or plastic during the bending process. This will prevent machining marks from imprinting on the sheet, resulting in a smoother surface finish. By using cloth or plastic, you also reduce the chances of the sheet metal getting scratched or damaged during bending. Another way to avoid bend marks is to ensure that the tools used in the bending process are of high quality. Poor quality tools can cause deep and visible tool marks on the surface of the sheet metal. High-quality tools, on the other hand, produce lighter marks that are easier to remove or not visible at all. Finally, to avoid bend marks, the sheet metal should be properly secured during bending. Properly securing the sheet metal helps prevent it from shifting or shifting during bending, which could cause machining marks. To ensure that the sheet metal is properly secured, clamps and other securing devices should be used to hold the sheet firmly in place during the bending process. In summary, sheet metal bending is a critical process in manufacturing and is critical to achieving the desired surface finish. Bend marks can be a serious problem and can be avoided by covering the sheet metal with cloth or plastic during bending, using high quality tools, and properly securing the sheet metal during bending. By following these tips, you can avoid bend marks and achieve a nice finish free of machining marks. But I have to clarify that even use all method mentioned, we can make the outside free from marks. To make sure the precision tolerance of sheet metal parts, we can’t use cloth on the upper tool, then the inside marks will still be visible.

To avoid bend marks, the sheet metal should be covered with cloth or plastic during the bending process. This will prevent machining marks from imprinting on the sheet, resulting in a smoother surface finish. By using cloth or plastic, you also reduce the chances of the sheet metal getting scratched or damaged during bending. Another way to avoid bend marks is to ensure that the tools used in the bending process are of high quality. Poor quality tools can cause deep and visible tool marks on the surface of the sheet metal. High-quality tools, on the other hand, produce lighter marks that are easier to remove or not visible at all. Finally, to avoid bend marks, the sheet metal should be properly secured during bending. Properly securing the sheet metal helps prevent it from shifting or shifting during bending, which could cause machining marks. To ensure that the sheet metal is properly secured, clamps and other securing devices should be used to hold the sheet firmly in place during the bending process. In summary, sheet metal bending is a critical process in manufacturing and is critical to achieving the desired surface finish. Bend marks can be a serious problem and can be avoided by covering the sheet metal with cloth or plastic during bending, using high quality tools, and properly securing the sheet metal during bending. By following these tips, you can avoid bend marks and achieve a nice finish free of machining marks. But I have to clarify that even use all method mentioned, we can make the outside free from marks. To make sure the precision tolerance of sheet metal parts, we can’t use cloth on the upper tool, then the inside marks will still be visible. Products Details

To avoid bend marks, the sheet metal should be covered with cloth or plastic during the bending process. This will prevent machining marks from imprinting on the sheet, resulting in a smoother surface finish. By using cloth or plastic, you also reduce the chances of the sheet metal getting scratched or damaged during bending. Another way to avoid bend marks is to ensure that the tools used in the bending process are of high quality. Poor quality tools can cause deep and visible tool marks on the surface of the sheet metal. High-quality tools, on the other hand, produce lighter marks that are easier to remove or not visible at all. Finally, to avoid bend marks, the sheet metal should be properly secured during bending. Properly securing the sheet metal helps prevent it from shifting or shifting during bending, which could cause machining marks. To ensure that the sheet metal is properly secured, clamps and other securing devices should be used to hold the sheet firmly in place during the bending process. In summary, sheet metal bending is a critical process in manufacturing and is critical to achieving the desired surface finish. Bend marks can be a serious problem and can be avoided by covering the sheet metal with cloth or plastic during bending, using high quality tools, and properly securing the sheet metal during bending. By following these tips, you can avoid bend marks and achieve a nice finish free of machining marks. But I have to clarify that even use all method mentioned, we can make the outside free from marks. To make sure the precision tolerance of sheet metal parts, we can’t use cloth on the upper tool, then the inside marks will still be visible.

To avoid bend marks, the sheet metal should be covered with cloth or plastic during the bending process. This will prevent machining marks from imprinting on the sheet, resulting in a smoother surface finish. By using cloth or plastic, you also reduce the chances of the sheet metal getting scratched or damaged during bending. Another way to avoid bend marks is to ensure that the tools used in the bending process are of high quality. Poor quality tools can cause deep and visible tool marks on the surface of the sheet metal. High-quality tools, on the other hand, produce lighter marks that are easier to remove or not visible at all. Finally, to avoid bend marks, the sheet metal should be properly secured during bending. Properly securing the sheet metal helps prevent it from shifting or shifting during bending, which could cause machining marks. To ensure that the sheet metal is properly secured, clamps and other securing devices should be used to hold the sheet firmly in place during the bending process. In summary, sheet metal bending is a critical process in manufacturing and is critical to achieving the desired surface finish. Bend marks can be a serious problem and can be avoided by covering the sheet metal with cloth or plastic during bending, using high quality tools, and properly securing the sheet metal during bending. By following these tips, you can avoid bend marks and achieve a nice finish free of machining marks. But I have to clarify that even use all method mentioned, we can make the outside free from marks. To make sure the precision tolerance of sheet metal parts, we can’t use cloth on the upper tool, then the inside marks will still be visible. Featured Products

-

Precision CNC machining service including milling and turning with 3 axis and 5 axis machines

-

Get Your Sheet Metal Prototypes from a Trusted Factory - Custom Aluminum Auto Parts Manufacturing Services Available

-

Other custom metal works including Aluminum extrusion and die-casting

-

Buy Factory-Made Custom Galvanized Steel Brackets for Electrical Boxes

-

High-quality sheet metal welded component Custom aluminum welding assembly

-

Customized CNC machined aluminum parts with sandblasting and black anodizing

-

Find Top-Quality Customized Metal Parts with No Coating Needed | Factory Direct Pricing

-

Customized metal parts which require no coating in specified areas

-

Urethane casting for rapid prototypes and low volume production

-

Stainless steel sheet metal bracket with black powder coating custom sheet metal parts

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours