CNC Machining Precision Parts Suppliers & Manufacturers: A Manufacturing Process

When it comes to manufacturing high-precision/'>precision parts, CNC machining is a go-to solution for many companies. This process involves the use of computer-controlled machines that can perform complex operations with high accuracy, speed, and efficiency. CNC machining has revolutionized the way parts are manufactured, enabling companies to produce high-quality components with consistent tolerances and minimal waste.

CNC, or computer numerical control, is a technology that has been around for decades. It has evolved from simple punch-card systems to advanced computer systems that are capable of controlling multiple axes of movement simultaneously. In CNC machining, the operator inputs a design into the computer which then translates it into instructions for the machine. The machine then follows these instructions to perform the desired operation.

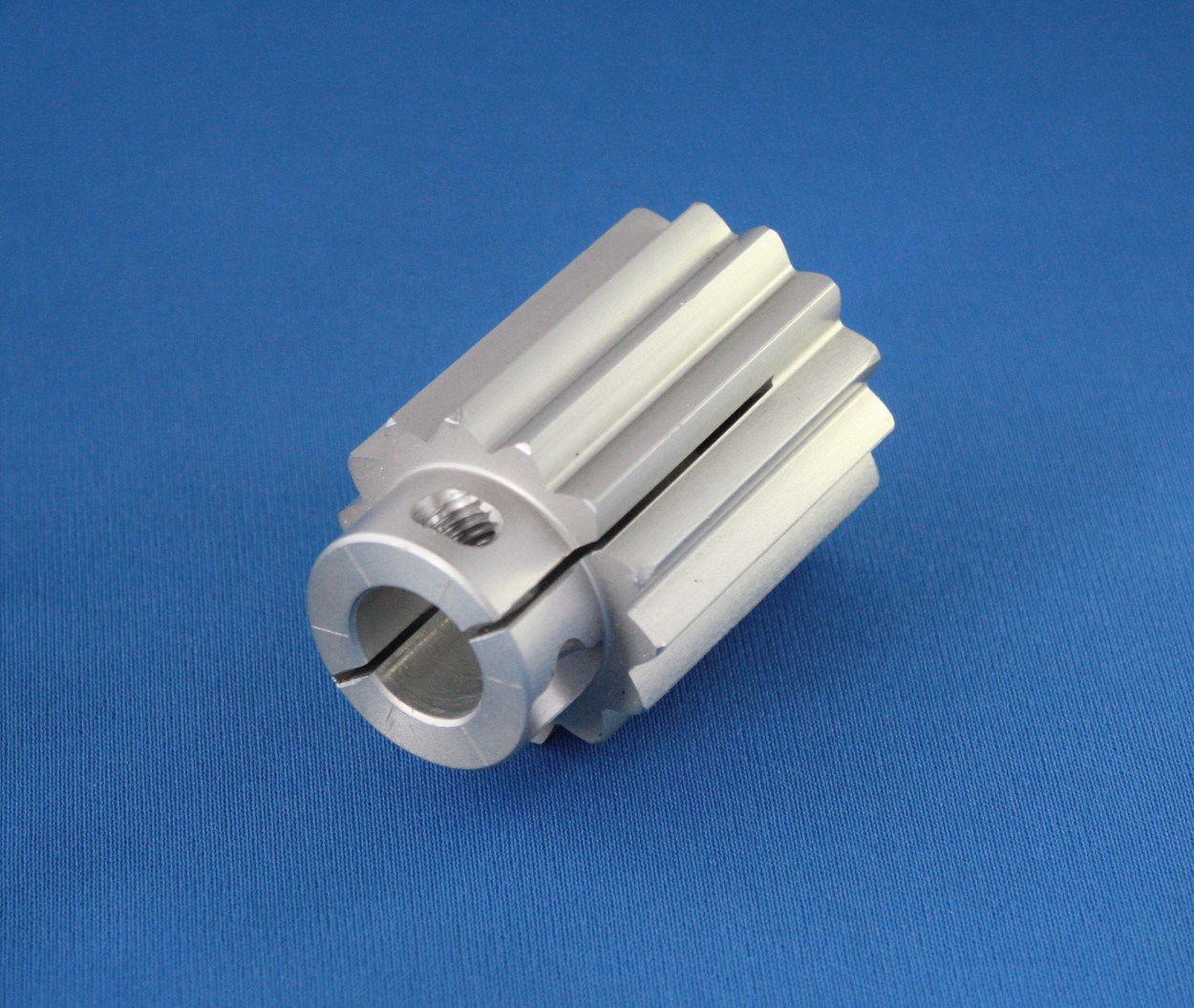

CNC machining can be used to produce a range of high-precision parts, including gears, bearings, engine components, medical devices, aerospace components, and many others. The process has many advantages over traditional machining methods. CNC machines are more accurate, more efficient, and more versatile than their older counterparts. They can perform complex operations with ease and produce parts with minimal operator intervention.

One of the key benefits of CNC machining is its ability to produce identical parts with high accuracy and consistency. This is particularly important in industries such as aerospace, medical, and automotive, where precision and reliability are critical. CNC machining can achieve tolerances as low as a few microns, making it ideal for producing parts with tight specifications.

CNC machines can also work with a wide variety of materials, including metals, plastics, wood, and composites. This versatility makes CNC machining an attractive option for companies that need to produce parts from a range of materials.

Another advantage of CNC machining is its speed and efficiency. Modern machines can perform complex operations at high speeds, allowing manufacturers to produce parts quickly and cost-effectively. This efficiency also reduces waste and improves overall productivity, making CNC machining a sustainable and environmentally friendly option.

Attracting a high-quality CNC machining precision parts supplier and manufacturer is essential for companies that want to take advantage of this technologically advanced manufacturing process. This can help businesses to stay competitive, increase production quality, and reduce costs.

Choosing the right supplier and manufacturer is critical to the success of a CNC machining project. Factors such as experience, expertise, equipment, and reputation should be considered when selecting a supplier. It is also essential to consider whether the manufacturer can provide parts that meet the desired specifications and can deliver them on time and within budget.

Overall, CNC machining is a valuable manufacturing process that can help companies to stay competitive in an increasingly globalized marketplace. By working with a reputable and experienced CNC machining precision parts supplier and manufacturer, businesses can take advantage of this technology and improve their bottom line.