Founded as a small garage operation, HY Metals has expanded to include seven wholly-owned manufacturing facilities, including four sheet metal factories and three CNC machining shops. This growth is a testament to the company's commitment to providing high-quality products and services to its customers.

The recent advancements in metal cutting processes are a result of HY Metals' continuous investment in research and development. The company has always been at the forefront of technological innovation, and these latest developments are a clear reflection of that.

One of the key goals for HY Metals is to improve the efficiency and precision of its metal cutting processes. By doing so, the company aims to enhance the quality of its products while also reducing production times and costs. These improvements will not only benefit the company but also its customers, who will receive better products at competitive prices.

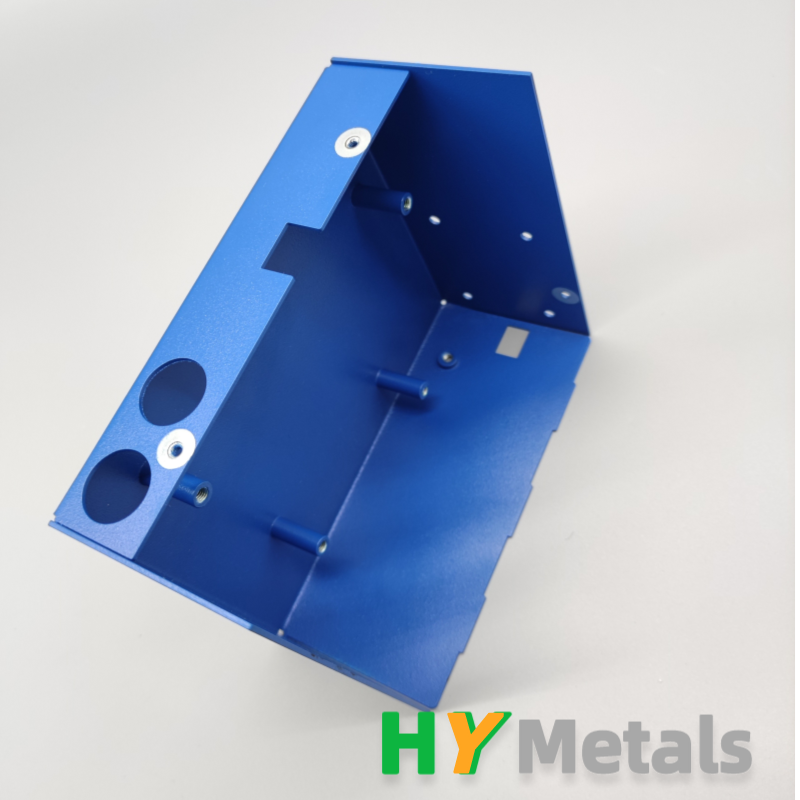

The new metal cutting processes developed by HY Metals incorporate the latest technologies and techniques in the industry. This includes the use of advanced cutting tools, precision machinery, and computer-aided design (CAD) software. By leveraging these tools, the company is able to achieve unprecedented levels of accuracy and consistency in its metal cutting processes.

Moreover, the new processes also allow HY Metals to work with a wider range of materials, including stainless steel, aluminum, copper, and various alloys. This flexibility opens up new opportunities for the company, as it can now cater to a more diverse set of customer needs and requirements.

In addition to the technical advancements, HY Metals has also streamlined its workflow and production processes to further enhance its metal cutting capabilities. This includes optimizing the use of resources, reducing waste, and improving overall productivity. As a result, the company is able to deliver faster turnaround times and meet tight deadlines without compromising on quality.

The significance of these developments cannot be overstated. As a company that serves various industries, including automotive, aerospace, electronics, and more, HY Metals' improved metal cutting processes will have far-reaching implications. Customers can expect better products with tighter tolerances and superior surface finishes, ultimately improving the performance and reliability of their end products.

But perhaps the most important aspect of these advancements is the impact it will have on HY Metals' competitive position in the market. By staying ahead of the curve in terms of technology and innovation, the company is able to differentiate itself from its competitors and secure its position as a leader in the industry.

Looking ahead, HY Metals is committed to further refining its metal cutting processes and exploring new opportunities for growth and expansion. With a strong focus on customer satisfaction and continuous improvement, the company is well-positioned to continue its upward trajectory and solidify its reputation as a top-tier provider of sheet metal and precision machining solutions.

In conclusion, the recent breakthrough in metal cutting processes is a significant milestone for HY Metals, reflecting the company's dedication to innovation and excellence. Customers can expect better products, improved turnaround times, and competitive prices as a result of these advancements. HY Metals is poised for even greater success in the future, thanks to its ongoing commitment to technological advancement and customer satisfaction.