CNC machining is a manufacturing process that has revolutionized the way precision parts are made. It has replaced traditional manual machining methods and has become the go-to process for making high-quality and complex parts. This is because CNC machines are controlled by computers, which ensures greater accuracy and consistency in the process. In this blog, we will delve deeper into CNC machining precision parts suppliers and manufacturers and how they have contributed to the advancement of the industry.

CNC Machining Process

CNC machining is a process that involves the use of computerized control systems to dictate the movement of machine tools. It involves the use of a computer-aided design (CAD) software, which enables the creation of a 3D model of the part to be machined. This 3D model is then uploaded to the CNC machine, which follows the instructions to cut and shape the raw material into the desired shape.

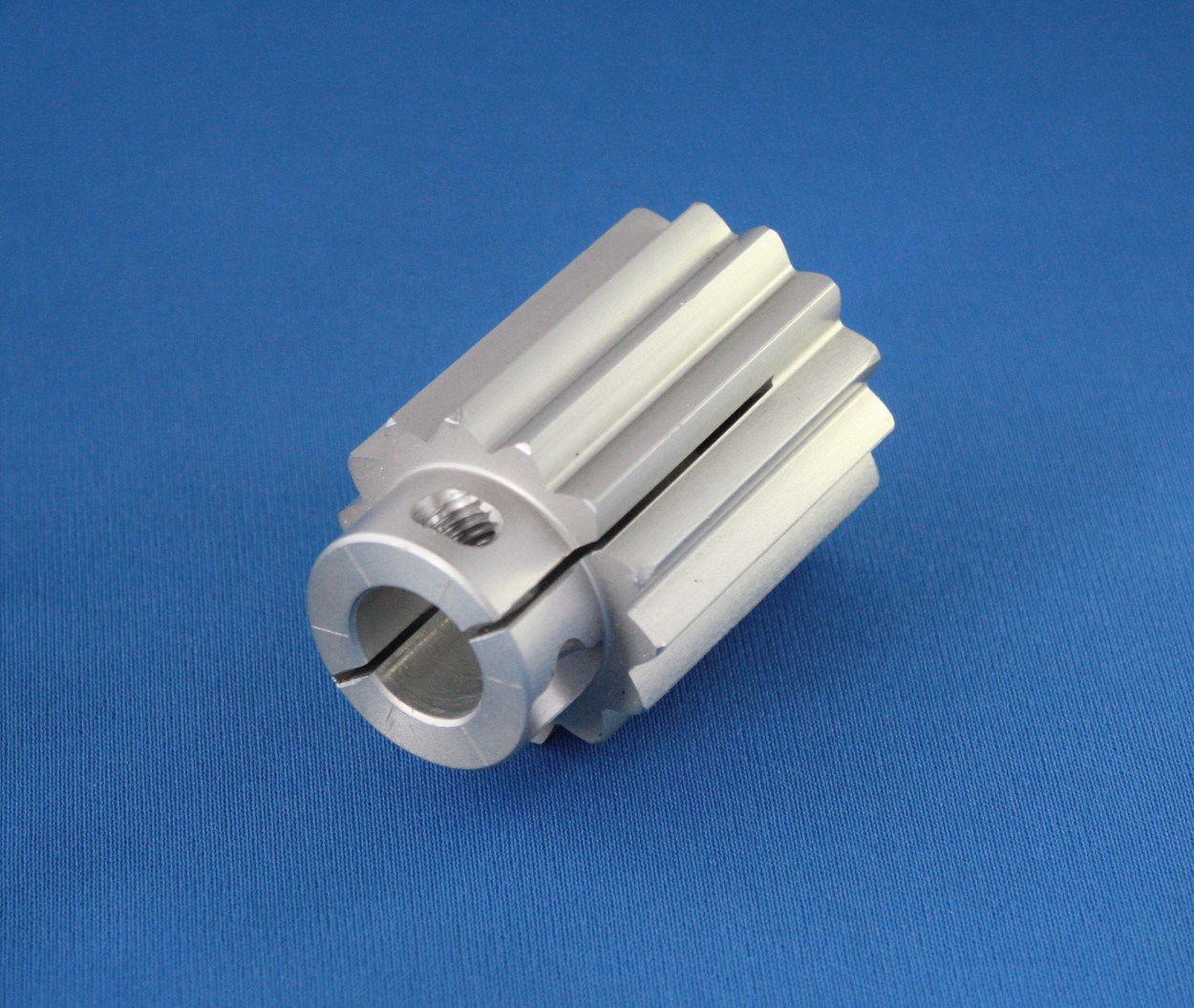

The CNC machine typically consists of various tools, including drilling, milling, and turning tools. The machine uses these tools to cut, shape, and drill the raw material into the desired finished product. CNC machines can be programmed to make complex shapes and designs that would be impossible with traditional manual machining methods.

Applications of CNC Machined Precision Parts

CNC machined precision parts are widely used in various industries, including aerospace, automotive, medical, and electronics, among others. These precision parts are used in critical parts of machines, equipment, and other devices, where accuracy and precision are required. Some of the commonly CNC machined parts include:

- Engine Parts

- Hydraulic Parts

- Aircraft Parts

- Electronic Components

- Medical Devices

- Defense Equipment

- Machine Tools

- Industrial Equipment

CNC Machining Precision Parts Suppliers & Manufacturers

CNC machining precision parts suppliers and manufacturers provide a full range of services, including CNC machining, design, prototyping, and assembly. They use state-of-the-art CNC machines and software to create high-quality and complex parts. The suppliers and manufacturers work with a wide range of materials, including metals, plastics, and ceramics, to create the desired parts.

To ensure quality and reliability, the suppliers and manufacturers follow strict quality control procedures to ensure that the parts meet the desired specifications. They also use advanced inspection equipment to ensure that the parts meet the required tolerance levels.

Why Choose CNC Machined Precision Parts?

CNC machined precision parts offer several benefits over traditional manual machining methods. Some of the advantages include:

1. Greater Accuracy and Consistency

CNC machines are controlled by a computer, which ensures greater accuracy and consistency in the machining process. This means that the finished parts are more precise and have a higher level of quality.

2. Higher Production Rate

CNC machines can operate continuously, which means they can produce more parts in a shorter time than traditional manual machines. This makes them ideal for high-volume production runs.

3. Improved Efficiency and Cost Savings

CNC machines are more efficient than traditional machining methods, which means they can save time and reduce costs. This is because they require less manual labor and can operate unattended for longer periods.

Conclusion

CNC machining precision parts suppliers and manufacturers have transformed the manufacturing industry by providing high-quality and complex parts. The use of CNC machines ensures greater accuracy and consistency in the machining process, which translates to higher quality parts. CNC machined precision parts are used in critical parts of machines, equipment, and devices, where accuracy and precision are required. By choosing CNC machined precision parts, you can enjoy greater accuracy and consistency, higher production rates, and cost savings.