CNC machining is an advanced manufacturing technology that is widely used in the production of various industrial components. CNC stands for Computer Numerical Control, which refers to a computer-controlled machine tool that can perform complex operations with precision and repeatability. Among various materials that CNC machining can handle, aluminum is one of the most commonly machined materials due to its favorable properties for a wide range of applications. In this blog, we will explore the versatility of CNC machining for aluminum parts machining.

Aluminum is a lightweight and durable metal that has excellent thermal and electrical conductivity, corrosion resistance, and machinability. It is widely used in various industries, such as aerospace, automotive, electronics, construction, and consumer goods. To produce aluminum parts with high quality and efficiency, CNC machining has become a preferred method for many manufacturers.

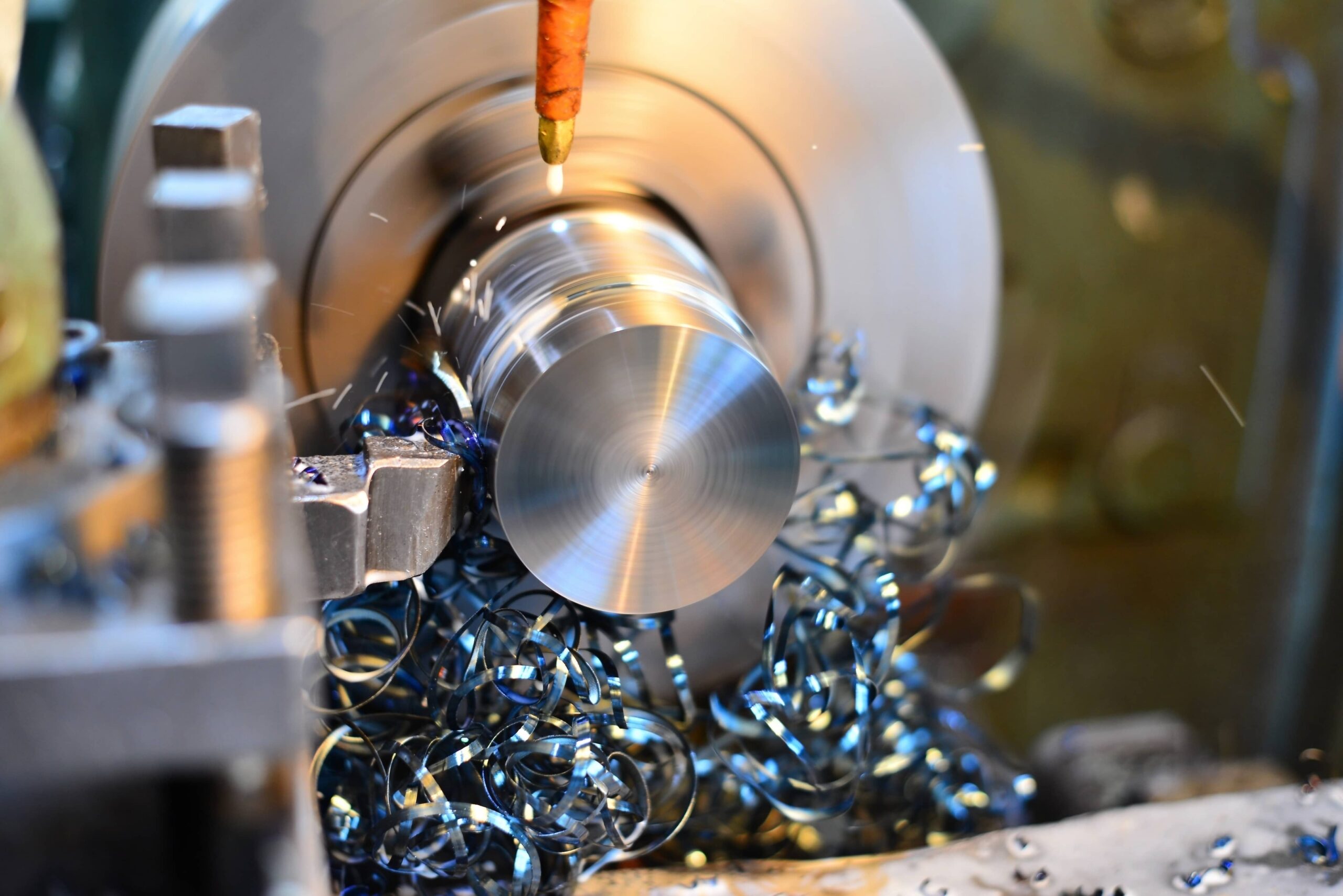

CNC machining allows for precise cuts, drills, milling, and turning operations that can produce complex shapes and surfaces with tight tolerances. The process involves programming a computer-aided design (CAD) file into a CNC machine, which then uses cutting tools to remove material from a block of aluminum according to the programmed instructions. The result is an accurate and consistent outcome that meets the desired specifications.

There are several advantages of using CNC machining for aluminum parts machining. First, CNC machining can produce parts in large volumes with consistent quality, reducing the risk of errors and waste. Second, CNC machines can operate continuously without human intervention, saving time and labor costs. Third, CNC machining can handle a wide range of shapes and sizes, from simple to complex designs. Fourth, CNC machines can work with various alloys and grades of aluminum, depending on the specific properties required for the application.

To ensure the best results for aluminum parts machining, it is essential to choose a reliable CNC machining service provider with expertise in machining aluminum. Xiamen Jingjing Die Casting Co., Ltd., for example, is a leading manufacturer of CNC machining, CNC machining parts, stainless steel machining components, with extensive experience in the aerospace, medical, industrial, and automotive industries. Their capabilities include precision machining, surface finishing, assembly, and packaging, and they are committed to meeting the highest quality standards and customer requirements.

In conclusion, CNC machining is a versatile and advanced technology for aluminum parts machining that offers many benefits for various industries. With CNC machining, manufacturers can produce high-quality, complex parts with precision and efficiency, resulting in cost savings, improved productivity, and customer satisfaction. If you need aluminum parts machining services, consider partnering with a trusted manufacturer like Xiamen Jingjing Die Casting Co., Ltd. to achieve your desired outcomes.