Established in 2010, HY Metals has experienced remarkable growth over the years, expanding from a small garage to a network of 7 wholly-owned manufacturing facilities, including 4 sheet metal factories and 3 CNC machining shops. With a strong focus on continuous improvement and innovation, the company has consistently strived to upgrade their capabilities and offerings to meet the evolving needs of their customers.

The latest development in their plating services is a testament to HY Metals' commitment to providing high-quality solutions. By integrating advanced plating technologies into their manufacturing processes, they aim to significantly enhance the performance and longevity of the products they produce. This initiative is poised to benefit a wide range of industries that rely on precision components and parts, including aerospace, automotive, electronics, and more.

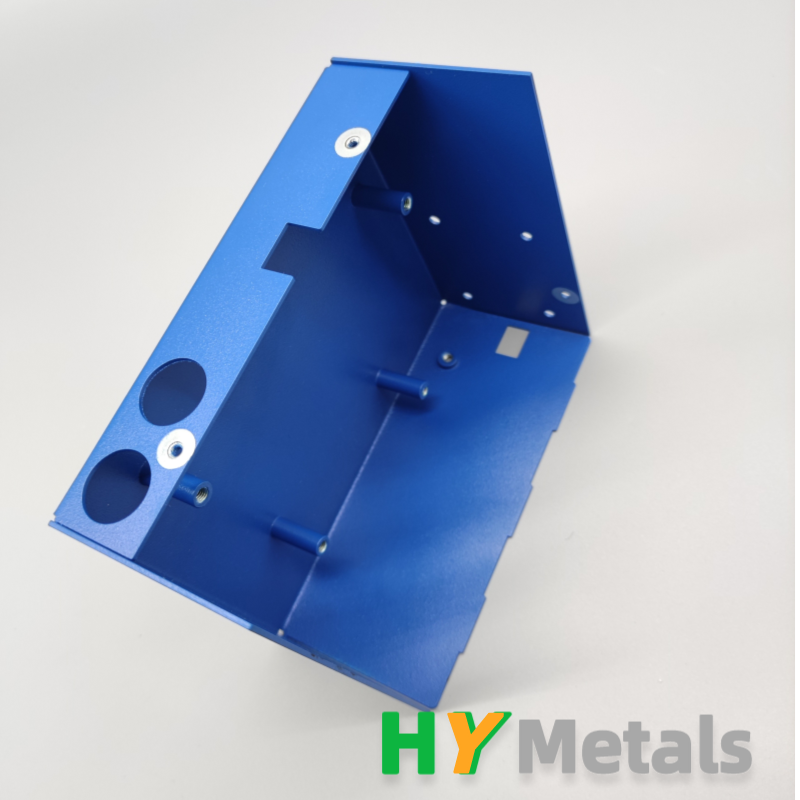

The enhanced plating capabilities will enable HY Metals to offer superior corrosion resistance, improved wear resistance, and enhanced aesthetic appeal for their products. This is particularly crucial for industries where components are subjected to harsh operating environments or demanding applications. By investing in state-of-the-art plating technologies, the company is positioning itself as a reliable partner for businesses seeking top-notch sheet metal and precision machined products.

In addition to the technical advantages, the new plating services are also aligned with HY Metals' sustainability goals. By utilizing eco-friendly plating processes and materials, the company is reducing its environmental footprint while delivering value-added solutions to its customers. This reflects their holistic approach to conducting business, where they prioritize both performance and environmental responsibility.

The introduction of advanced plating services is expected to bolster HY Metals' competitive position in the market. As the industry landscape continues to evolve, the ability to offer premium plating solutions will set the company apart and attract new opportunities for growth and collaboration. With their proven track record of excellence in sheet metal fabrication and precision machining, the addition of enhanced plating capabilities further solidifies their position as a comprehensive manufacturing partner.

Moreover, the expansion of their plating services underscores HY Metals' responsiveness to customer needs. By investing in technologies that directly enhance the quality and longevity of their products, the company demonstrates its commitment to delivering value beyond the conventional scope of manufacturing. This customer-centric approach is ingrained in their corporate culture and is exemplified by their willingness to adapt and evolve in line with market demands.

Going forward, HY Metals is poised to leverage its advanced plating services as a cornerstone of its value proposition. As customer expectations continue to rise, the company is well-positioned to meet and exceed these demands by offering premium plating solutions that align with the highest industry standards. This strategic initiative underscores their dedication to innovation, quality, and customer satisfaction.

Overall, the introduction of advanced plating services at HY Metals marks a significant milestone in the company's journey. With a solid foundation built on expertise and a forward-thinking approach to manufacturing, the addition of enhanced plating capabilities further cements their status as a leading provider of sheet metal and precision machined products. Customers can expect to benefit from superior quality, enhanced durability, and sustainable solutions, positioning HY Metals as a preferred partner for their manufacturing needs.